Samsung SDI Faces Rising Costs Amid US Tariff Pressures

Samsung SDI $006405.KS has recently drawn attention in the financial markets following its announcement on Friday. The South Korean firm indicated that impending US tariffs are set to increase production costs for electric vehicle (EV) batteries manufactured within the States. This development is spurred by the reliance on imported materials and components, essential for maintaining competitiveness in a rapidly evolving industry.

Tariff Tensions and the EV Battery Landscape

During a telephone conference reviewing Q1 performance, Executive Vice President Kim Yoon-tae explained that although EV battery production occurs domestically in the United States, the majority of critical materials come from abroad. As a result, the impact of tariffs may not affect assembly processes directly, but they will likely escalate overall expenditure due to increased import costs. This subtle yet crucial dynamic underscores the intricate relationship between global trade policies and high-tech manufacturing.

Unpacking Financial Implications and Supply Challenges

A closer look at Samsung SDI's operations reveals an interplay of factors that influence cost structures:

1. Identification of tariff pressures on imported raw materials and components.

2. A reassessment of cost strategies to mitigate the impact of higher import prices.

3. Identification of potential market adjustments to balance increased production costs and competitive pricing.

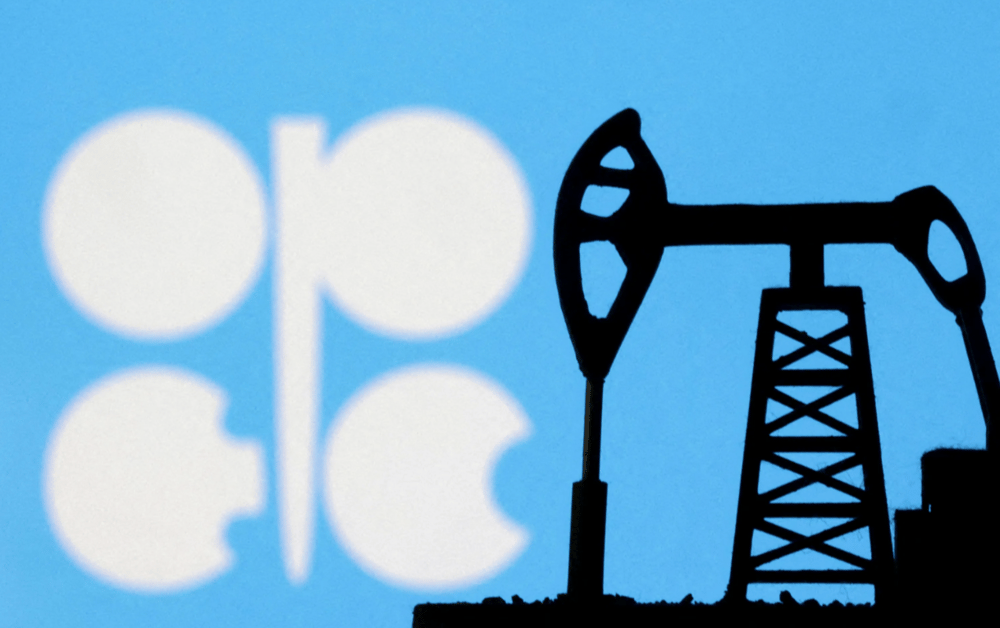

The Ripple Effects Across the Trade Ecosystem

- Escalated production expenses could lead to recalibrated pricing strategies within the EV market.

- Extended supply chains might prompt a review of sourcing strategies for critical components.

- Financial outcomes seen in quarterly reports may reflect pressures wrought by tariff-induced spend.

- Global trade dynamics are likely to influence broader market sentiment in the tech and automotive sectors.

Navigating a Future Defined by Global Trade Variables

Samsung SDI’s latest disclosure serves as a catalyst for a broader discussion on how international trade dynamics shape the manufacturing costs of advanced technologies. As tariffs redefine standard operational costs, companies involved in the production of EV batteries may witness a ripple effect throughout their supply chains. The firm’s insights into managing imported components highlight an adaptive approach to mitigating financial impacts amidst evolving regulatory landscapes.

Comments